TECHNOLOGIES

CNC

Milling

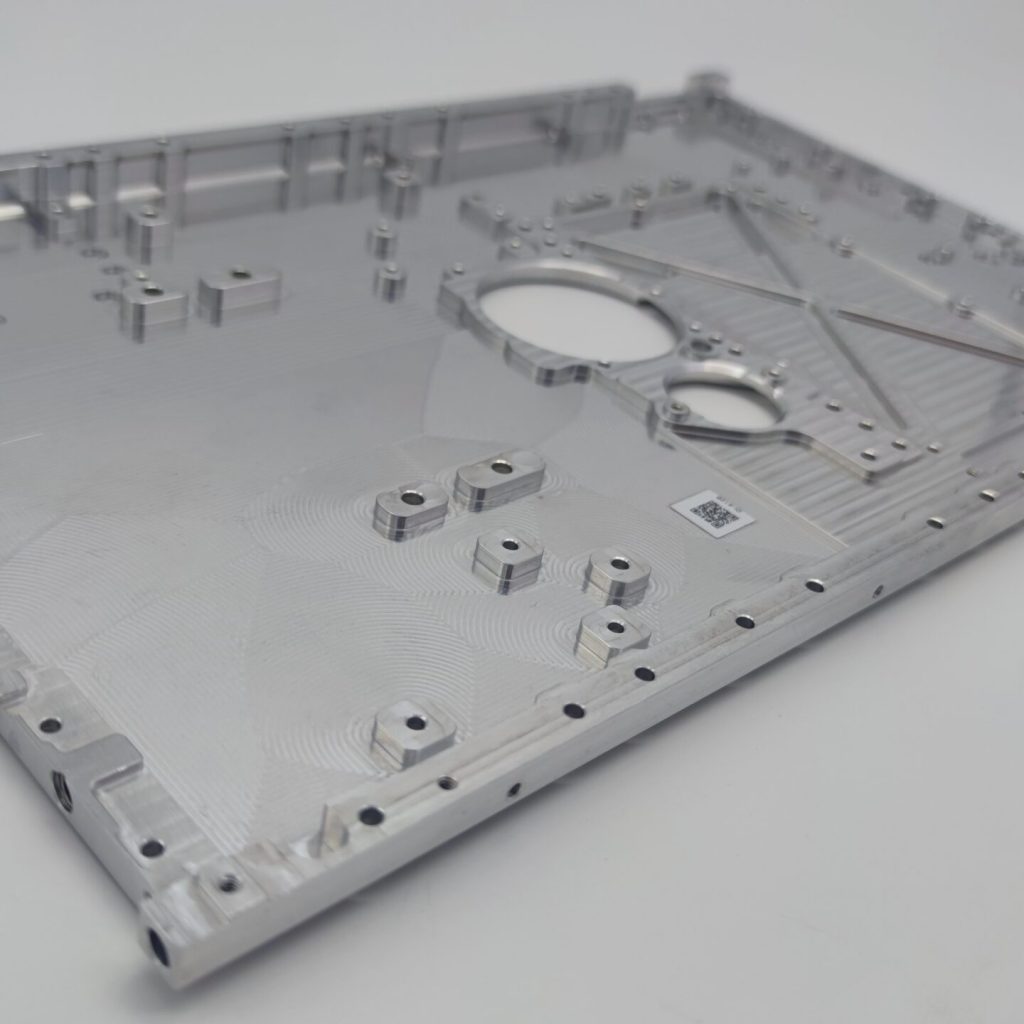

CNC milling is a subtractive machining technology, which uses the power of computer numerical control (CNC) to obtain parts of high precision and complexity.

In this process the machine executes a specific program which contains all the information for the production of one or more pieces. With this technology a large number of different materials can be processed including metals, plastics, woods, ceramics and composite materials.

TECHNOLOGIES

CNC

Milling

ADVANTAGES

1

Speed and flexibility, both for unique pieces and for series production.

2

Maximum precision, with the possibility of requesting certificates and inspection reports.

3

Customization of products in an efficient way, creating unique and tailor-made pieces

MILLING

3-axis CNC Milling

ONEDGE has the latest generation machinery dedicated to 3-axis milling processing and a large variety of accessories and tools to manage all customer needs.

We also have a machine with a vacuum table dedicated to milling thin materials, plastic sheets, aluminum and brass sheets and plates.

Dimensions

maximum

1600x650 mmWarehouse

raw materials

More than 1300KgTolerance

minimum

-+0,005 mm3-axis CNC Milling

3-axis CNC Milling

3-axis CNC Milling

MILLING

5-axis Milling

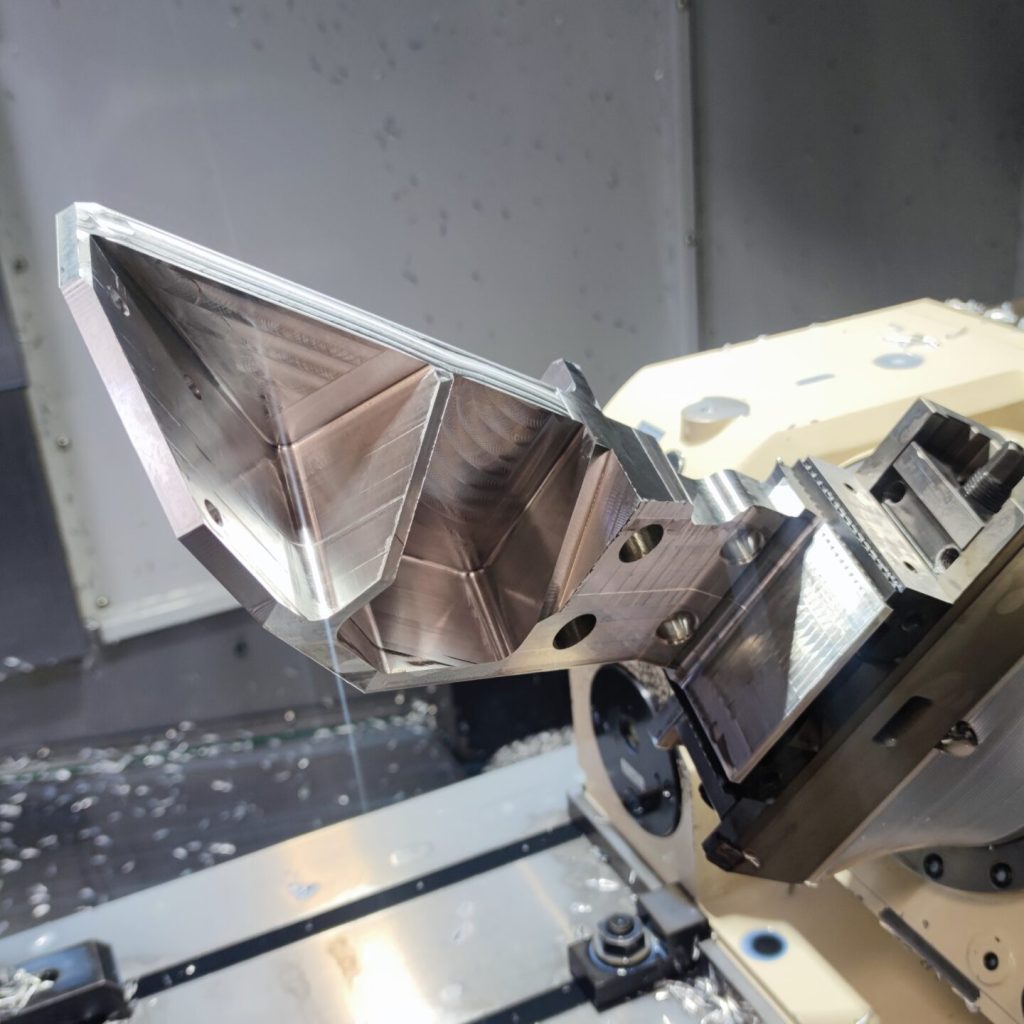

5-axis milling offers a significant advantage due to its ability to move the tool in five directions simultaneously, introducing two additional rotary axes, allowing you to work on curved and complex surfaces in a single setup. This translates into greater flexibility, a reduction in processing times and a significantly higher quality of the finished piece. 5-axis milling allows you to create complex geometries that would be difficult or impossible to achieve with 3-axis machines, opening up new possibilities in industries such as aerospace and automotive.

Dimensions

maximum

Ø380x300 mmWarehouse

raw materials

More than 850 KgTolerance

minimum

-+0,005 mm5-axis Milling

5-axis Milling

5-axis Milling

MATERIALS AND FINISHES

- Aluminum: AW2024, AW5083, AW5754, AW6082, AW7075, AW7021, AW2017, AW6026LF

- Copper: CW004A

- Brass: CW614N, CW510L, CW511

- Bronze: CC333G, CC483K

- Titanium: Ti6Al4V

- Unalloyed steels: 1.0038 (S235JR), 1.1730 (C45W), 1.0045 (S355JR)

- Low alloy steels: 1.6510(39NiCrMo4), 1.1725 (42CrMo4), 1.7218 (25CrMo4)

- High alloy steels: 1.2312 (40CrMnMoS8), 1.2316 (X38CrMo16), 1.2714 (55NiCrMoV7)

- Tool steels: 1.2842 (90MnCrV8)

- Stainless steels: 1.4307 (AISI304L), 1.4404 (AISI316L), 1.4542 (17-4PH), 1.4028 (AISI420), 1.4305 (AISI303)

- Thermoplastics: POM, PA6, PA66GF30, PE, PP, PVC, PC, PMMA, PEEK, UHMWPE, PTFE

- Thermosets: PU, PUR

- Composites: FR4, CFP