TECHNOLOGIES

3D Printing services

3D printing, or additive manufacturing (AM), is a revolutionary process that builds three-dimensional objects layer by layer, adding material until the final form is achieved. Unlike traditional subtractive manufacturing methods, which remove material to create a desired shape, 3D printing offers a more efficient and flexible approach to product development and production.

Integrating 3D printing into the manufacturing process enable us to streamline production, reduce costs, and accelerate time-to-market. Whether it's rapid prototyping, functional prototyping or the production of small series of final parts, we can find the right solution to realize every project.

ADVANTAGES

1

Accelerates the prototyping process: rapid iteration, design refinement and faster product development cycles

2

Material is only used where it's needed, reducing material waste compared to traditional subtractive manufacturing

3

Empowers the creation of intricate and complex shapes, unlocking new design possibilities and driving innovation

3D PRINTING

3D Printing services

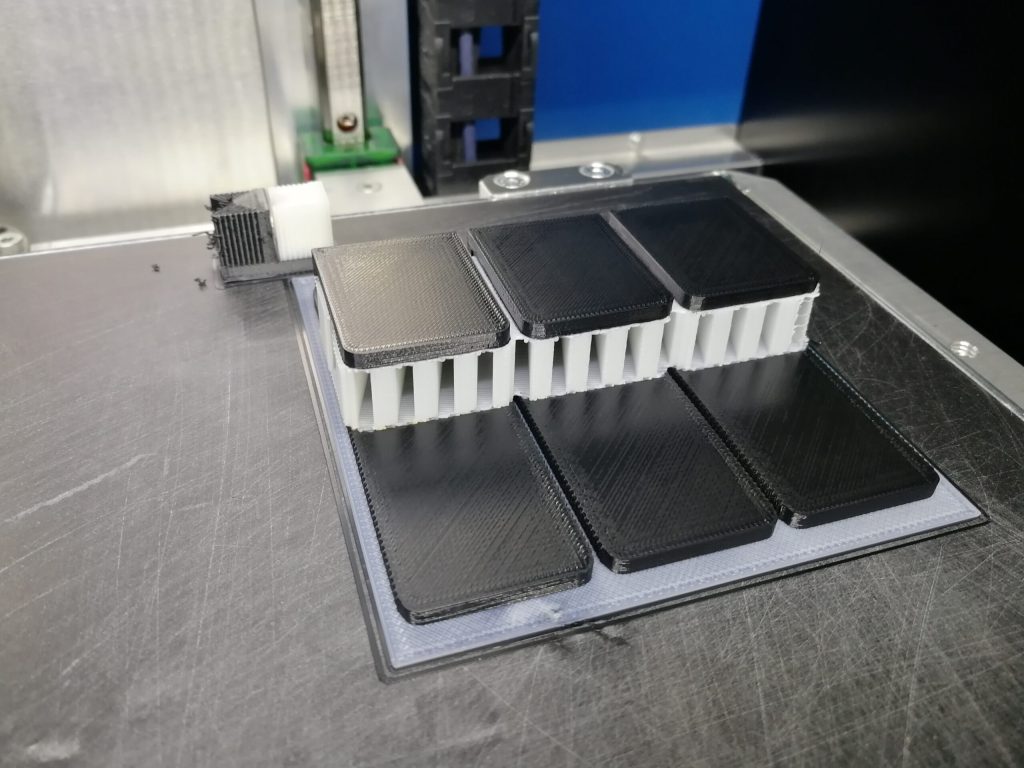

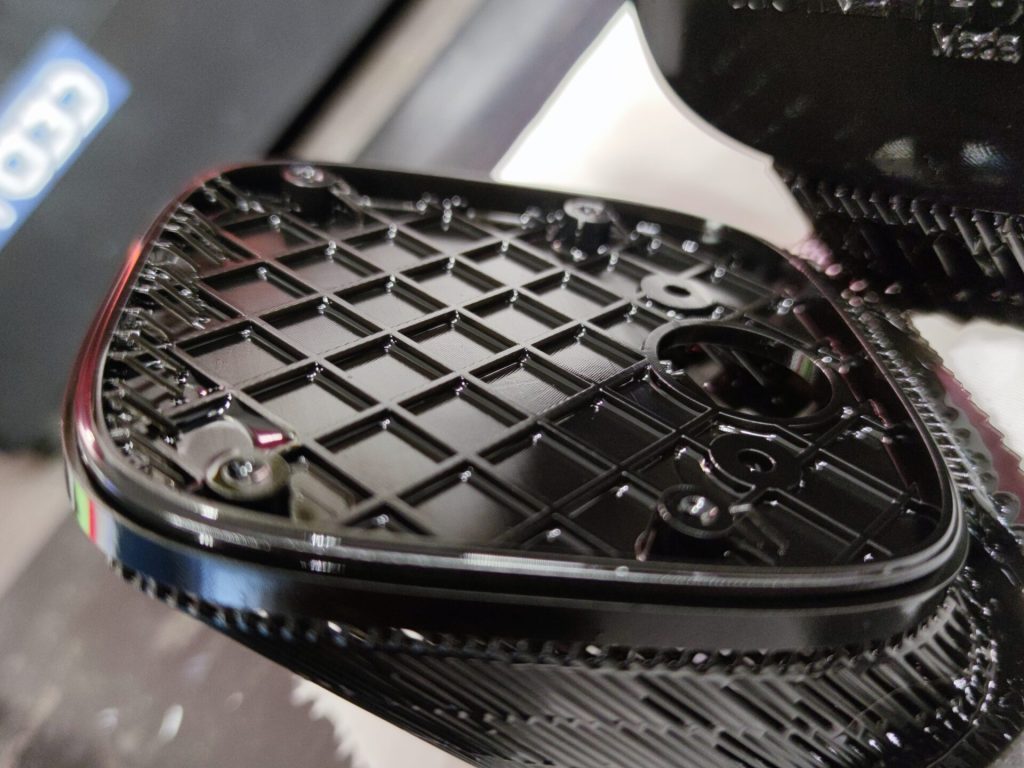

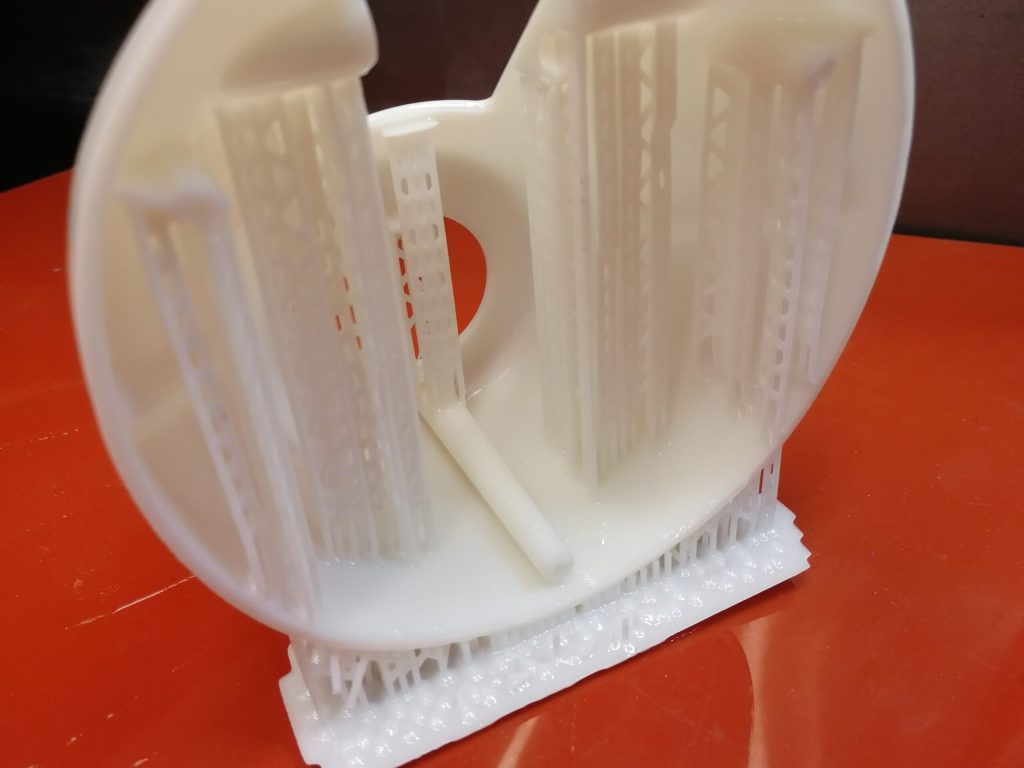

FDM / FFF

FDM 3D printing is an additive manufacturing process that involves the deposition of molten material, layer by layer, to create three-dimensional objects from a digital model. Using thermoplastic filaments of different nature, this technology offers wide design freedom and the possibility of creating complex geometries.

The main advantages of FDM 3D printing lie in its accessibility, versatility of materials and ability to quickly produce functional prototypes. With a wide choice of thermoplastic materials, it offers a quick and reliable solution for the realization of your projects.

Dimensions

maximum

430x300x200 mmTolerance

minimum achievable

-+0,20 mmNumber

of realizable pieces

1 to 500 pcs/lot3D Printing services

3D Printing services

3D Printing services

3D PRINTING

3D Printing services

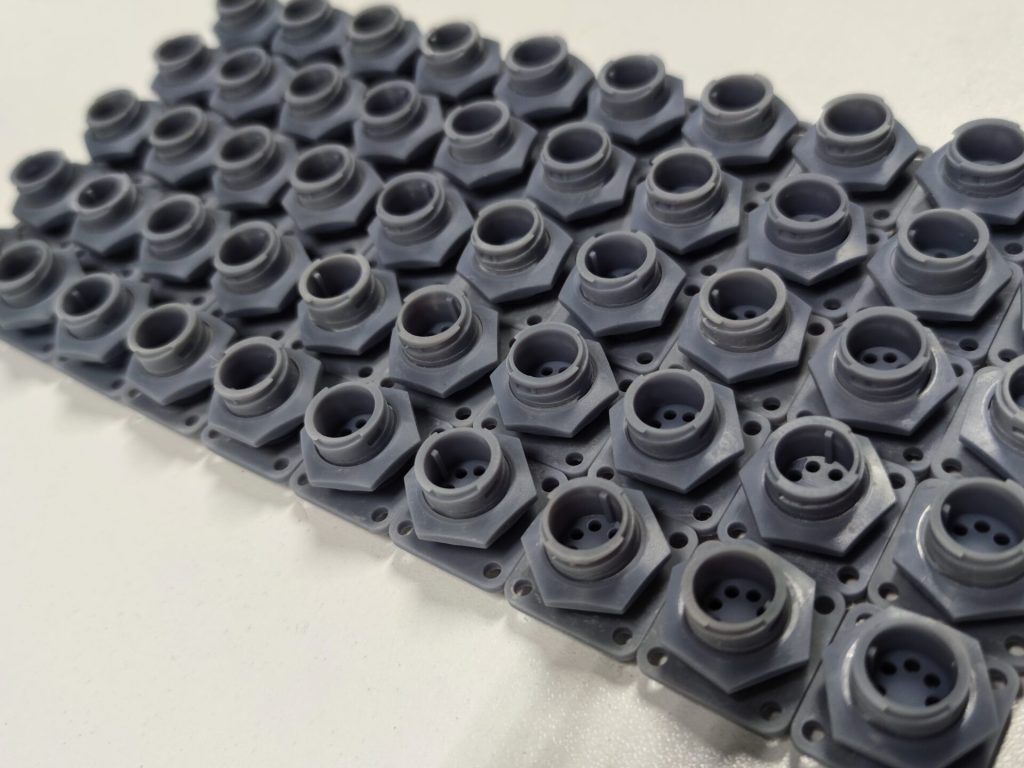

SLA / DLP / mSLA

SLA (Stereolitography), DLP (Digital Light Processing) and mSLA (masked Stereolitography) 3D printing technologies represent a significant advancement in the field of additive manufacturing. Based on the principle of polymerization of light-curing resins, these techniques allow the creation of three-dimensional objects with a high level of detail and dimensional precision. Using an ultraviolet light source, two-dimensional sections of a digital model are solidified layer by layer inside a vat of resin.

The choice of the most suitable technology depends on the specific needs of the project, considering factors such as the precision required, the production speed and the available budget.

Dimensions

maximum

200x140x300 mmTolerance

minimum achievable

-+0,05 mmNumber

of realizable pieces

1 to 5000 pcs/batch3D Printing services

3D Printing services

3D Printing services

Materials and Finishes

- ABS (FDM)

- PETG (FDM)

- PLA (FDM)

- ASA (FDM)

- PA6 (FDM)

- PA12 (FDM/SLS/MJF)

- PA11 (SLS/MJF)

- PC (FDM)

- PC/ABS (FDM)

- PBT (FDM)

- PEEK (FDM)

- PEKK (FDM)

- PEI (FDM)

- PPSU (FDM)

- TPU (FDM/MJF)

- TPE (FDM)

- Rigid (SLA/MSLA/DLP)

- Tenacious (SLA/MSLA/DLP)

- ABS-like (SLA/MSLA/DLP)

- Flexible (SLA/MSLA/DLP)

- High temperature (SLA/MSLA/DLP)

- Flame retardant (SLA/MSLA/DLP)

- Transparent (SLA/MSLA/DLP)

- Glass fiber filled polymers (FDM/SLS)

- Carbon fiber filled polymers (FDM/SLS)

- Polymers with inert fillers (FDM)