TECHNOLOGIES

Complementary processing

In addition to the production of your prototypes and small batches, ONEDGE accompanies you in all processing phases, offering a complete and personalized service. Our advanced in-house technologies allow us to obtain surface finishes of the highest level, both from an aesthetic and functional point of view.

We have a full range of services from injection molding to MIG/TIG welding, up to spray and powder coating. Our technical expertise allows us to work with a wide range of materials and create high-precision components. Thanks to the integration of all technologies, we offer turnkey solutions, guaranteeing the highest quality and reliability of the finished products.

ADVANTAGES

1

Internal production tailored to each project, ensuring high quality finishes.

2

In-depth product knowledge and total control over production for excellent results.

3

Fast delivery: eliminating intermediaries, faster and more reliable delivery.

COMPLEMENTARY PROCESSING

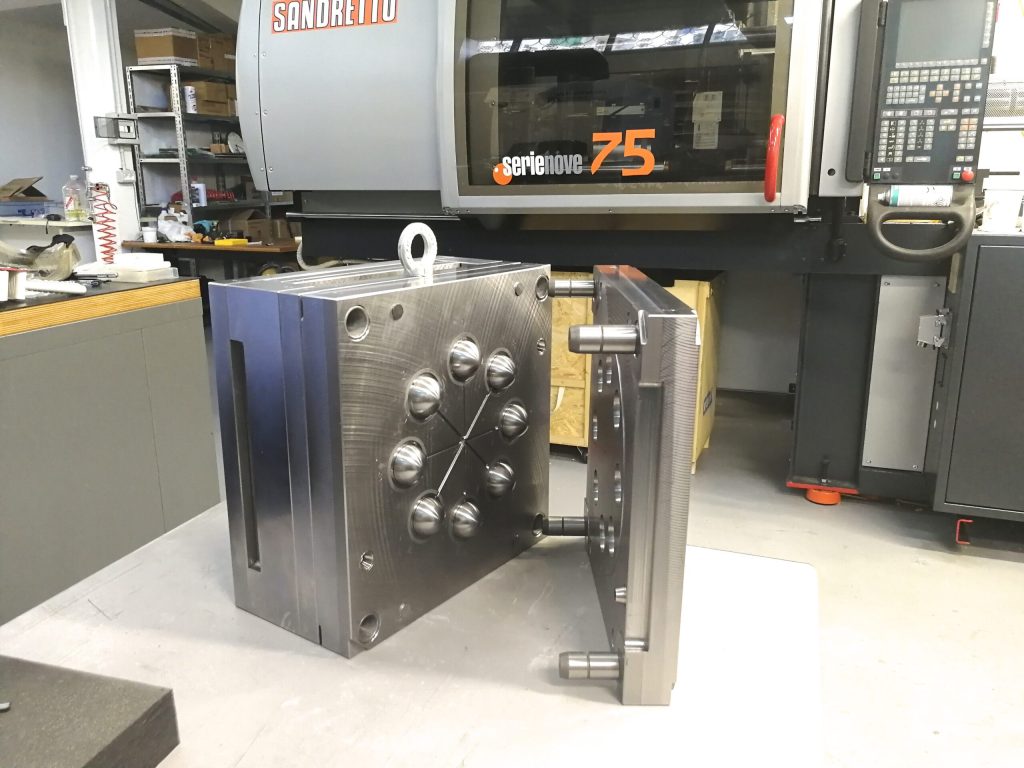

Injection molding

It is an industrial process that allows to create plastic objects with complex and precise shapes. Imagine having a plastic material, such as polystyrene or PVC, that is heated until it becomes fluid. This molten material is then injected at high pressure into a metal mold, which has the exact shape of the object you want to obtain. Once the material cools and solidifies, a perfect copy of the mold is obtained.

Productivity

up to 2000 pieces/day

Size

from 5 to 110 g/piece

Tonage

75 tons

Injection molding

Injection molding

Injection molding

COMPLEMENTARY PROCESSING

TIG and MIG

welding

TIG and MIG welding are two fundamental techniques in joining metals, although they have significant differences. TIG, which uses an infusible tungsten electrode and a separate metal input, guarantees joints of the highest quality and precision, but requires greater manual skill. MIG, on the other hand, uses a continuous wire as electrode and filler material, making it quicker and less complex, ideal for mass production. In summary, TIG is preferred for precision work on thin metals and special alloys, while MIG is suitable for thicker sheet metal and high-volume production. The choice between the two depends on the specific needs of the job, the type of material and the desired level of finish.

COMPLEMENTARY PROCESSING

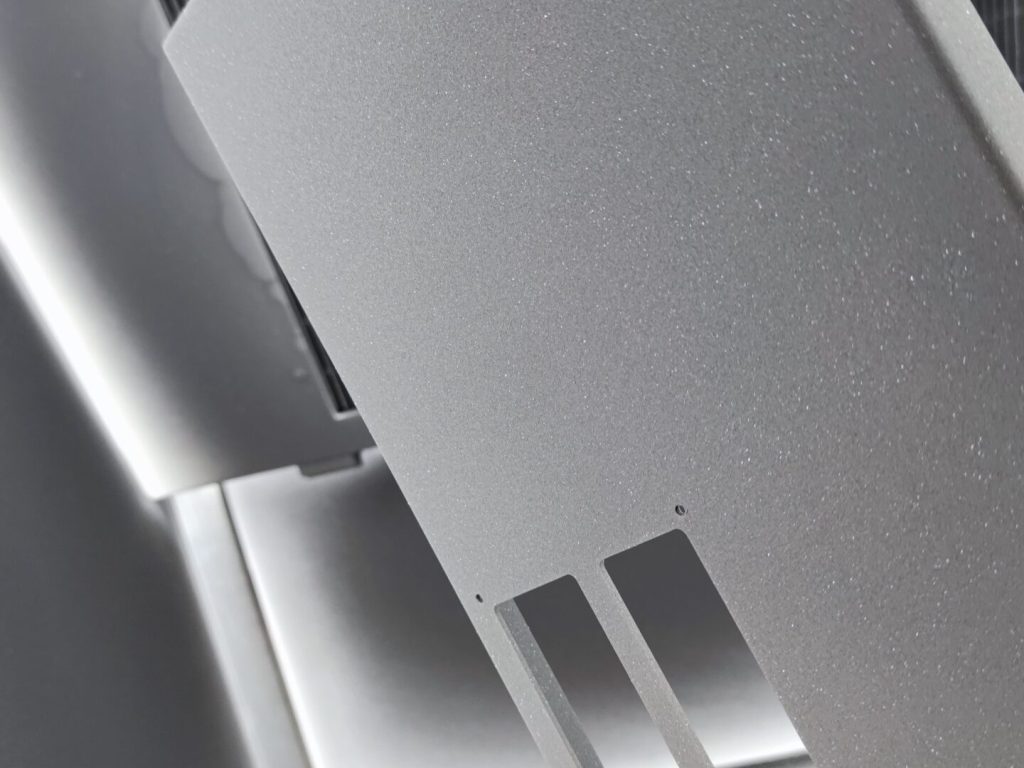

Spray and powder

painting

Spray and powder painting are two fundamental techniques for protecting and beautifying surfaces, but they differ significantly in the process and characteristics of the final coating: spray painting uses an atomized liquid paint, offering versatility and speed of application, but requires the use of solvents and longer drying times. Powder coating uses a resin powder applied electrostatically and baked in an oven, ensuring a more resistant, environmentally friendly and long-lasting coating, but is less suitable for glossy finishes.

The choice between the two techniques depends on the specific needs of the product: spray painting is ideal for complex surfaces and finishing work, while powder coating is perfect for products that require long-term protection and flawless aesthetics.

Spray and powder painting

Spray and powder painting

Spray and powder painting