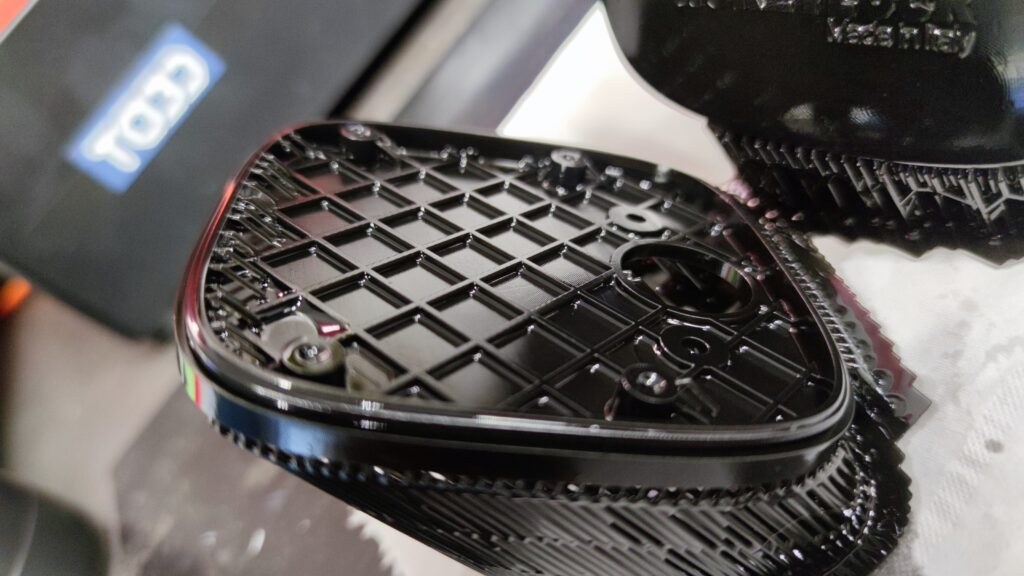

Unlike traditional subtractive manufacturing methods, where material is removed from a larger block, 3D printing creates objects by adding material layer by layer, following a digital blueprint. The process begins with creating a 3D model of the desired object, usually using computer-aided design (CAD) software. This model is then sent to the 3D printer, which “slices” it into very thin horizontal layers. A material (plastic, metal, ceramic, etc.) is deposited layer by layer, solidifying and creating the final three-dimensional object.

Benefits of additive manufacturing

🔸 Flexibility: 3D printing allows for the creation of complex and customized geometries that would be difficult or impossible to achieve with traditional methods.

🔸 Rapid prototyping: going from an idea to a physical prototype is much faster, significantly accelerating development cycles.

🔸 Mass customization: it is possible to produce large quantities of customized objects, reducing costs and production times.

🔸 Reduction of waste materials: you only use the material needed to create the object, you generate less waste than traditional methods.

🔸 Small series production: 3D printing is ideal for small series production, making it accessible even to small businesses.

Limitations of additive manufacturing

Despite the numerous advantages offered by 3D printing, there are still some limitations.Producing large objects can take considerable time, slowing down production processes. In addition, the initial cost of industrial 3D printers and specialty materials can be high, representing a barrier to entry for some companies. The surface quality of the objects produced can vary greatly depending on the technology and material used, and sometimes may not meet the standards required by some industries.

Finally, mechanical properties of 3D printed objects may differ from those obtained with traditional manufacturing methods, limiting their use in some applications that require high performance.

The future of additive manufacturing

The future of additive manufacturing is promising. As technology advances and costs decrease, more and more industries will adopt this innovative production method, opening up new possibilities and applications.

ONEDGE and 3D printing

ONEDGE is at the forefront of custom 3D printers. Designed and built in-house, these machines allow us to be extremely responsive to market needs and offer innovative solutions to our customers.

To learn more about this technology, the materials we use and the different types of 3D printing we work with, you can read this dedicated page.