Fixtures are a universal component in automation systems and are essential for precise positioning and holding during manufacturing processes: it’s designed to hold, support, or guide a workpiece, ensuring accuracy, consistency, and efficiency in various applications, from machining and assembly to inspection and testing.

There are several types of fixtures, each dedicated to specific needs and processes:

- Machining fixtures: used to hold workpieces securely during machining operations like milling, drilling, and turning.

- Welding fixtures: position and hold components in place for welding, ensuring proper alignment and joint quality.

- Assembly fixtures: used to align and hold components together during assembly processes, facilitating efficient and accurate joining.

- Inspection fixtures: designed to hold workpieces in a specific position for inspection, ensuring compliance with quality standards.

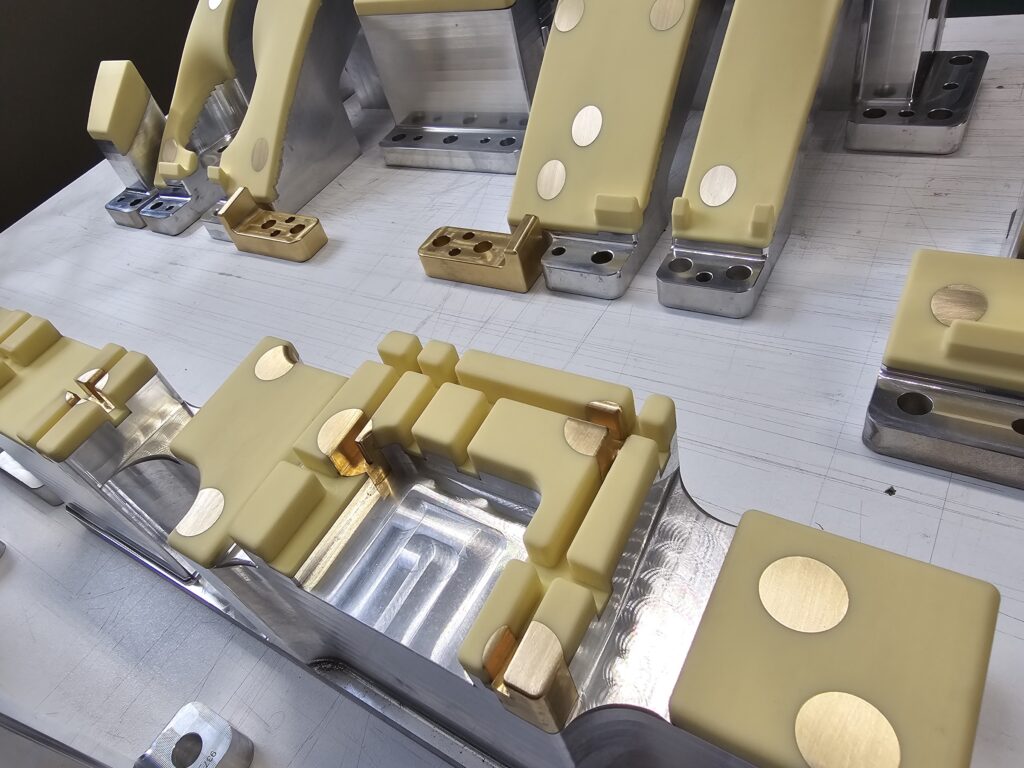

At ONEDGE, we specialize in ultrasonic welding fixtures as they play a crucial role in ensuring the quality of the weld joint and preserving the integrity of component surfaces. Given the delicate finishes of many parts (transparent, chrome-plated, painted, polished, mirror-finished), it’s essential to use fixtures specifically designed for this type of process. Made of inert and non-abrasive materials, these fixtures must provide a secure and stable hold on the component, preventing any risk of scratches or deformation. Additionally, to prevent localized overheating and subsequent surface deterioration, it is advisable to use integrated cooling systems or apply specific lubricants.

The production of ultrasonic welding fixtures requires a complex and highly precise manufacturing process. It starts with the milling of aluminum, a material chosen for its lightness and strength. Subsequently, vacuum casting of polyurethane rubber is performed, allowing for the creation of complex shapes and the absorption of vibrations during welding. To contain the adhesive and ensure uniform distribution, 3D printed containers are used. The milled aluminum is then chemically satin-finished to obtain a matte finish resistant to scratches. Depending on the specific needs of the customer, brass inserts can be integrated to increase rigidity or create custom anchor points.