We take your project to the next level

We prepare it for additive manufacturing, or simplify it to reduce production costs. We consider materials, average times and availability on the market, together with the accessible production technologies based on the number of pieces to be produced to get you to the goal within the expected times and costs.

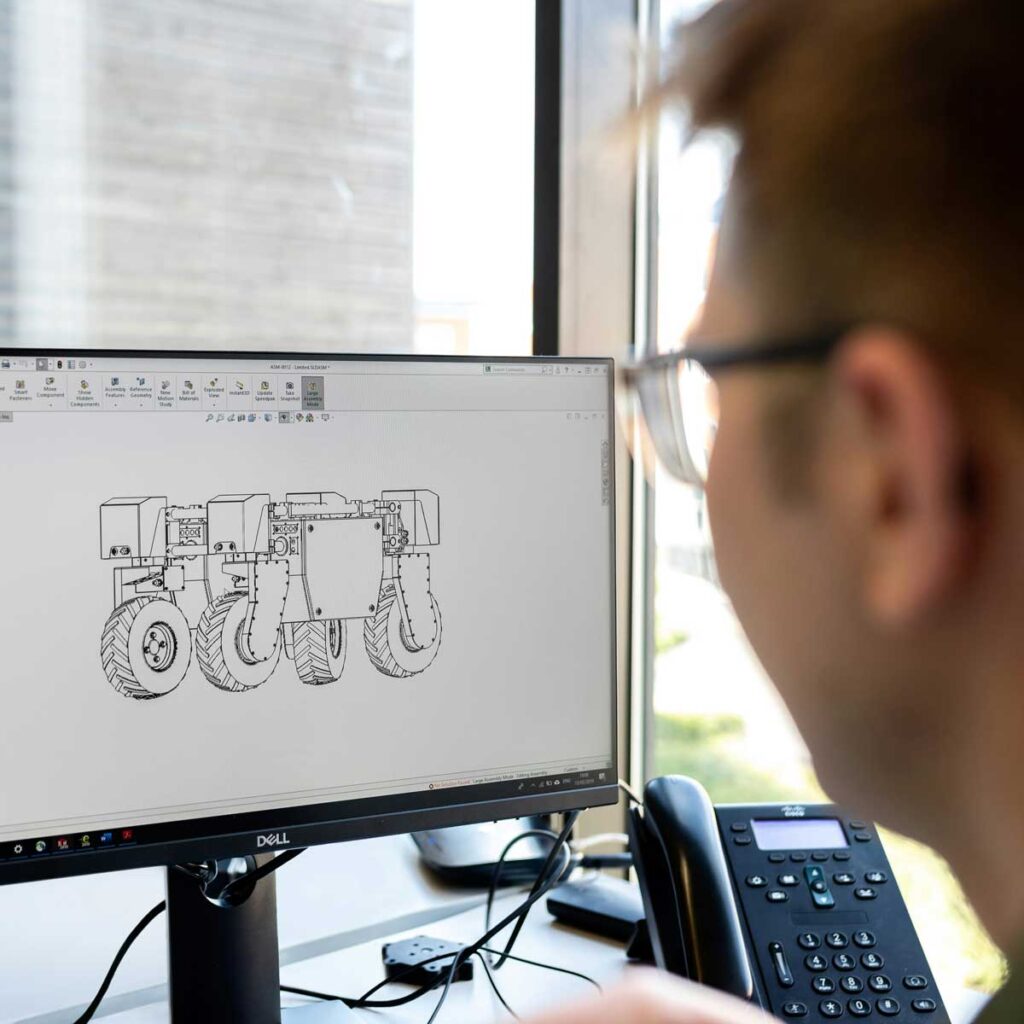

Through sophisticated finite element analysis (FEM), our engineers perform accurate structural calculations and preliminary checks on each component. This methodology allows us to predict the behavior of the product under different load conditions, optimizing the design and preventing potential problems. Thanks to FEM analysis, we can evaluate the strength, deformation and stability of each part, ensuring a robust and long-lasting final product.

ADVANTAGES

1

Reduction of errors and defects, identifying and anticipating problems through computer simulations and analyses

2

Choice and/or optimization of materials based on the chosen production process

3

Improved product performance, optimizing the characteristics based on the required useful life

SERVICES

- Selection of the most suitable materials based on the mechanical, chemical and thermal properties required by the component.

- Evaluation of the compatibility of the material with the chosen production process.

- Cost-benefit evaluation of various production techniques based on the batch requested.

- Adaptation of the component geometry to make the most of the potential of 3D printing (e.g. lattice structures, complex curved surfaces).

- Reduction in weight and volume of the component while maintaining the required performance.

- Optimize component orientation on the build platform to reduce production time, reduce supports, and improve surface quality.

- Analysis of the constraints and forces of a component to optimize weight and resistance.

- Reduction of the material actually used, which allows a reduction in both the times and costs of additive manufacturing.