TECHNOLOGIES

CNC

turning

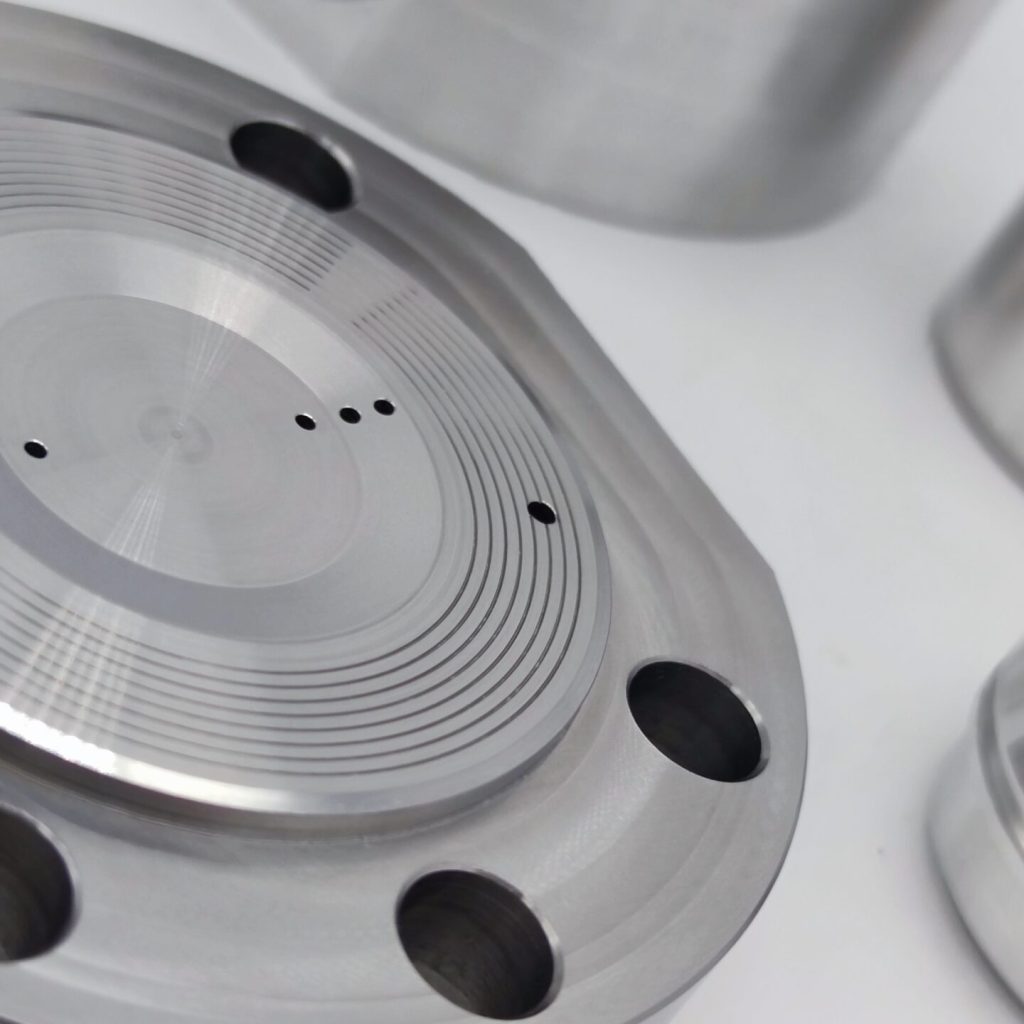

CNC turning is a key subtractive machining technology in the modern manufacturing industry. Using numerically controlled machine tools, this technique allows us to obtain mechanical components of high precision and geometric complexity, responding to the needs of different sectors, from automotive to aerospace.

TECHNOLOGIES

CNC

turning

ADVANTAGES

1

Precision, guarantee of a superior surface finish and greater compliance with design specifications.

2

High flexibility which allows the creation of complex geometries and reduced production times.

3

Better repeatability, ensuring that each piece produced is identical to the previous one ensuring consistent high quality.

TORNITURA

C-Y Axis Turning

ONEDGE offers advanced technology to produce complex turned parts in a single setup. Complex parts with lateral and front millings, eccentric parts, drilling and off-center radial and axial threads. All can be done directly during the turning phase, guaranteeing maximum precision (the piece maintains the same origin and operator positioning errors are eliminated) and automation.

The system is controlled by the company 4.0 system and controlled by our team using the latest generation CAD/CAM software.

Dimensions

maximum

Ø350x600 mmTolerance

minimum achievable

-+0,005 mmNumber

of realizable pieces

1 to 5000 pcs/batchC-Y Axis Turning

C-Y Axis Turning

C-Y Axis Turning

MATERIALS AND FINISHES

- Aluminum: AW2024, AW5083, AW5754, AW6082, AW7075, AW7021, AW2017, AW6026LF

- Copper: CW004A

- Brass: CW614N, CW510L, CW511

- Bronze: CC333G, CC483K

- Titanium: Ti6Al4V

- Unalloyed steels: 1.0038 (S235JR), 1.1730 (C45W), 1.0045 (S355JR)

- Low alloy steels: 1.6510(39NiCrMo4), 1.1725 (42CrMo4), 1.7218 (25CrMo4)

- High alloy steels: 1.2312 (40CrMnMoS8), 1.2316 (X38CrMo16), 1.2714 (55NiCrMoV7)

- Tool steels: 1.2842 (90MnCrV8)

- Stainless steels: 1.4307 (AISI304L), 1.4404 (AISI316L), 1.4542 (17-4PH), 1.4028 (AISI420), 1.4305 (AISI303)

- Thermoplastics: POM, PA6, PA66GF30, PE, PP, PVC, PC, PMMA, PEEK, UHMWPE, PTFE

- Thermosets: PU, PUR

- Composites: FR4, CFRP