TECHNOLOGIES

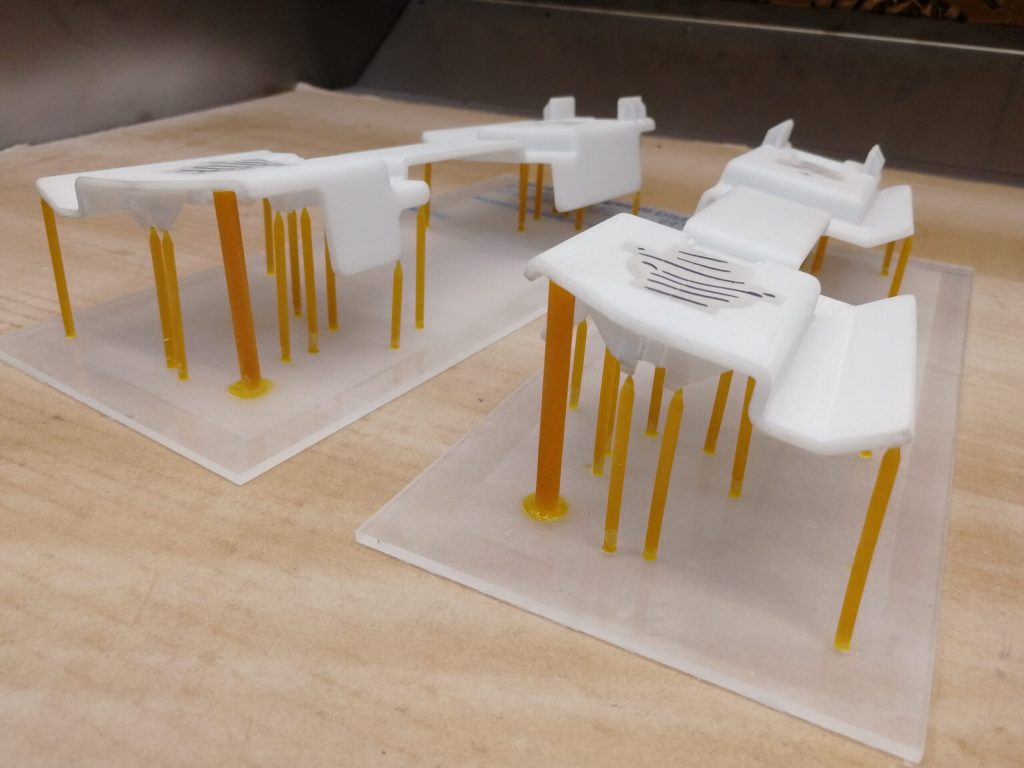

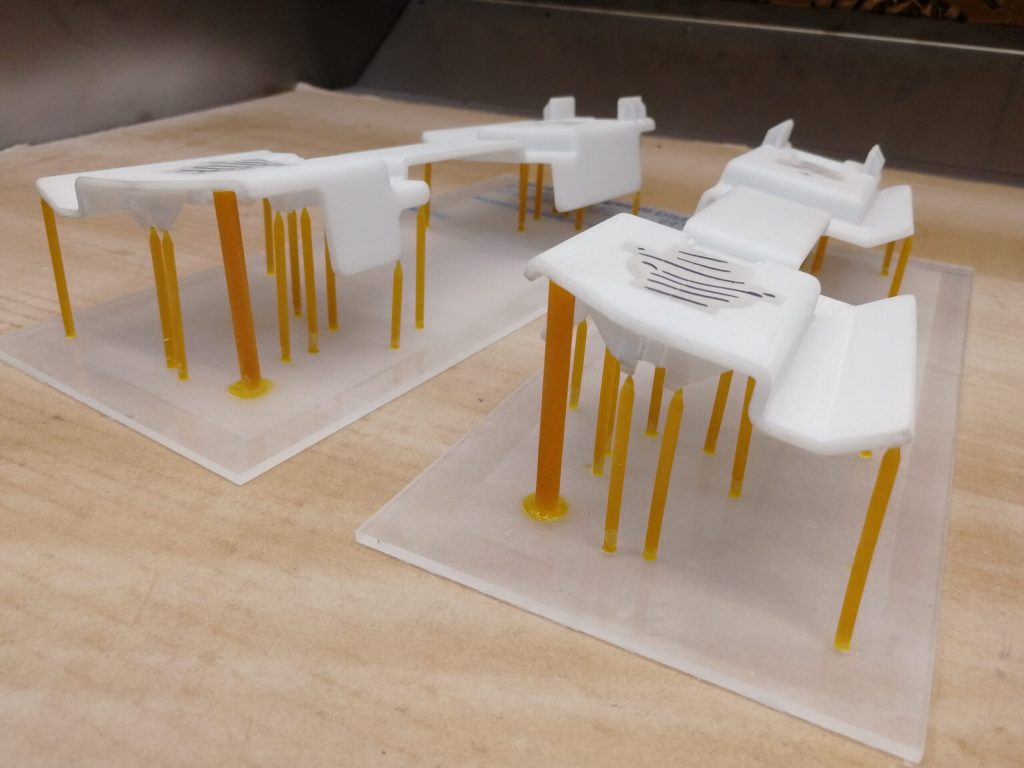

Vacuum casting

Vacuum casting is a process that allows you to create copies of prototypes and models in polyurethane resin with high precision and detail, being identical to a "master" model through the creation of one or more soft silicone molds.

It is possible to produce a small series (from 15 to 200 pieces) of the same model at a low cost compared to other production processes. The applications of vacuum casting are vast and involve different phases of a product's life cycle. On the one hand, it allows the creation of functional prototypes for pre-launch tests, allowing the ergonomics, aesthetics and performance of an object to be evaluated. On the other hand, it is ideal to produce small series and customized objects, such as conceptual models, limited series and tailor-made products, meeting the needs of an increasingly customization-oriented market.

ONEDGE has internally developed a specific vacuum casting process that allows us to obtain high quality definitive parts with rigid PU, semi-rigid PU flexible PU, PU rubbers of any hardness in Shore A, and silicone rubbers with hardness up to 45 Shore A.

ADVANTAGES

1

High-quality surface finish, ready for use without additional post-processing. It’s ideal for applications where aesthetics is key.

2

Quick turnaround: Silicone molds can be produced rapidly compared to metal molds, enabling faster prototyping.

3

Flexible material choices (plastics, resins, elastomers) allow to tailor properties like flexibility, durability, and heat resistance to specific applications.

VACUUM CASTING

PU Casting

PU casting is halfway between rapid prototyping and series production. Compared to 3D printing, it offers greater dimensional accuracy, better surface finishes and the ability to use a wide range of materials.

However, vacuum casting requires the making of molds, which can lead to higher initial costs. Compared to injection molding, vacuum casting is more flexible and allows for smaller volumes to be produced but offers similar quality in terms of surface finish and precision. The choice between these technologies depends on the specific needs of the project, considering factors such as production volume, the level of detail required and the available budget.

Dimensions

maximum

600x500x250 mmWeight

max. per casting

2 KgNumber

of realizable pieces

5 to 1000 pcs/lotPU Casting

PU Casting

PU Casting

VACUUM CASTING

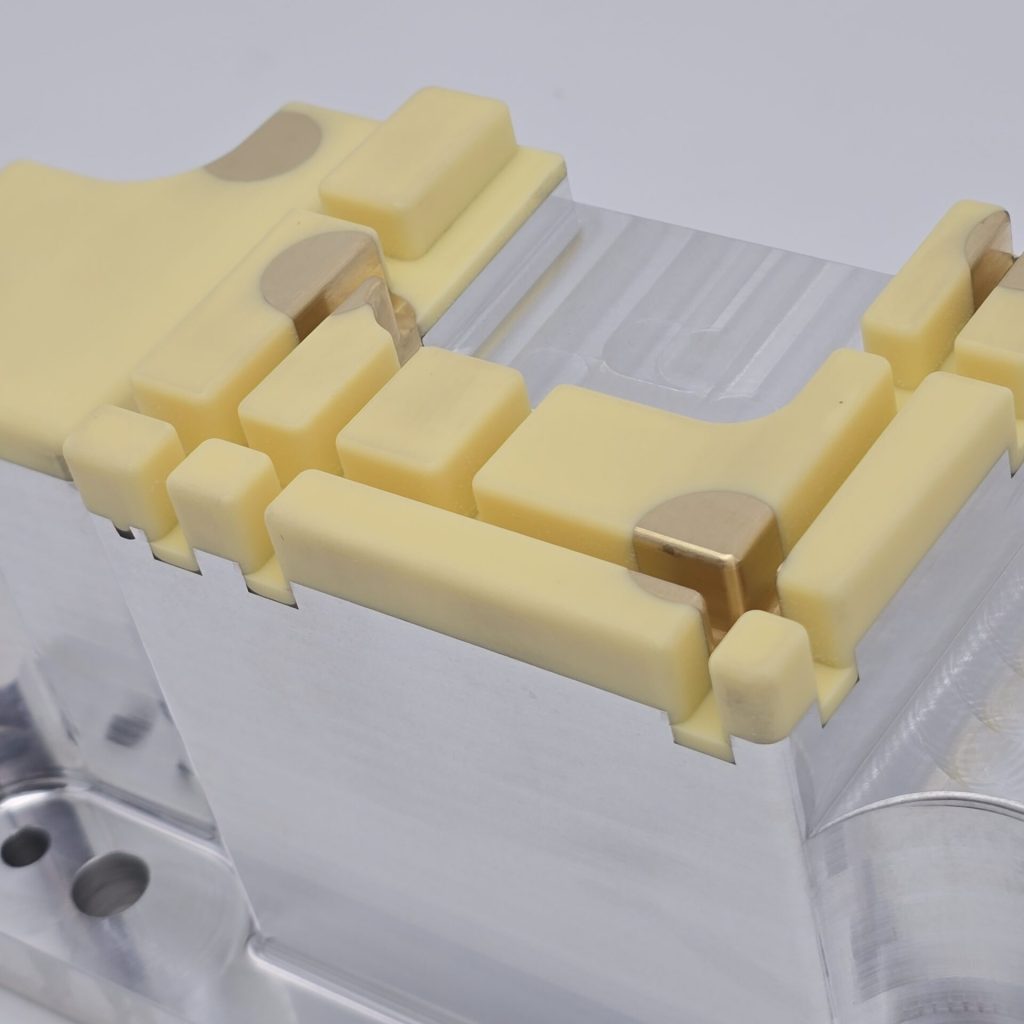

PUR Casting

ONEDGE's main production via vacuum casting concerns PU and silicone rubber parts, as the quality of these components significantly exceeds the counterpart made in #D printing, both in terms of mechanical resistance and surface finish. Furthermore, when the runs are limited, we can produce the molds directly in 3D printing, guaranteeing cost-effectiveness and speed of production compared to classic equipment made through mechanical processing.

Dimensions

maximum

1000x600x200 mmWeight

max. per casting

6 KgNumber

of realizable pieces

5 to 1000 pcs/lotPUR Casting

PUR Casting

PUR Casting

MATERIALS AND FINISHES

- FASTCAST

- MODEL

- CLEAR

- PP-like, HDPE-like

- ABS-like

- PA-like

- PC-like

- PMMA-like

- PA6-GF20

- PA-like

- PP-TD20 like

- PC/ABS-FR like

- FLAME RETARDANCE

- FOODGRADE

- PU formulations from 40 to 95 Shore A

- Wear-resistant PUR for ultrasonic welding masks and templates

- Silicones from 10 to 45 Shore A